Timber Flooring Options: Compare Lifewood Stabilised Solid® Timber Flooring To The Rest Of The Market

ALL OUR BOARDS ARE MADE WITH OUR PATENTED STABILISED SOLID® DESIGN

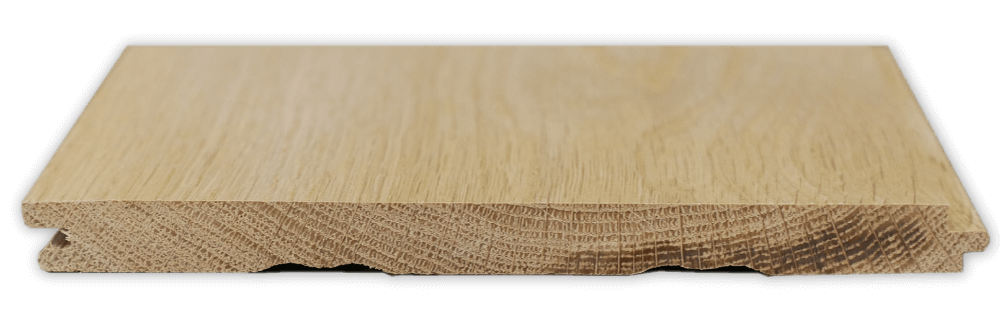

100% real timber from top to bottom

How do we compare to everything else on the market?

See all your alternative flooring options below.

Timber Flooring Market Options

![]() Can be sanded multiple times

Can be sanded multiple times

![]() Designed to be glued down

Designed to be glued down

![]() Extra long, wide boards

Extra long, wide boards

![]() Comes pre-finished

Comes pre-finished

![]() No messy sand and polish

No messy sand and polish

![]() Scratch resistant technology

Scratch resistant technology

![]() Moisture sealed all 6 sides

Moisture sealed all 6 sides

![]() Installed in days

Installed in days

![]() No part of the tree wasted

No part of the tree wasted

Installation Method: Direct Stick

Average Cost/Sqm: $89 – $220 (Supply only)

![]() Can be sanded multiple times

Can be sanded multiple times

![]() Designed to be glued down

Designed to be glued down

![]() Extra long, wide boards

Extra long, wide boards

![]() Comes pre-finished

Comes pre-finished

![]() No messy sand and polish

No messy sand and polish

![]() Scratch resistant technology

Scratch resistant technology

![]() Moisture sealed all 6 sides

Moisture sealed all 6 sides

![]() Installed in days

Installed in days

![]() No part of the tree wasted

No part of the tree wasted

Installation Method: Direct Stick

Average Cost/Sqm: $139 – $209 (Supply only)

![]() No messy sand and polish

No messy sand and polish

![]() Scratch resistant technology

Scratch resistant technology

![]() Installed in days

Installed in days

![]() 100% real timber

100% real timber

![]() Can be sanded multiple times

Can be sanded multiple times

![]() Designed to be glued down

Designed to be glued down

![]() Extra long, wide boards

Extra long, wide boards

![]() Moisture sealed all 6 sides

Moisture sealed all 6 sides

![]() No part of the tree wasted

No part of the tree wasted

Installation Method: Floating

Average Cost/Sqm: $69 – $139 (Supply only)

![]() No messy sand and polish

No messy sand and polish

![]() Scratch resistant technology

Scratch resistant technology

![]() Installed in days

Installed in days

![]() 100% real timber

100% real timber

![]() Can be sanded multiple times

Can be sanded multiple times

![]() Designed to be glued down

Designed to be glued down

![]() Extra long, wide boards

Extra long, wide boards

![]() Moisture sealed all 6 sides

Moisture sealed all 6 sides

![]() No part of the tree wasted

No part of the tree wasted

Installation Method: Direct Stick

Average Cost/Sqm: $139 – $209 (Supply only)

Timber Flooring Alternatives

A multilayered SPC (stone plastic composite) designed to imitate the natural look of timber flooring.

Installation Method: Floating

Average Cost/Sqm: $29 – $59 (Supply only)

Hybrid timber flooring is a combination of vinyl laminate flooring mixed with multiple elements such as limestone

Installation Method: Floating

Average Cost/Sqm: $49 – $99 (Supply only)

Carpet

Wool carpet is a premium fiber carpet option. It’s more durable than nylon and contains no artificial ingredients.

Average Cost/Sqm: $125 – $150 (Supply only)

Made from synthetic fiber and easily manufactured. This form of carpet is usually produced in low loop style to strengthen it’s low resilience to wear.

Average Cost/Sqm: $39 – $59 (Supply only)

Different Styles of Tile

Porcelain tiles are made from a clay mixture and kiln fired at very high temperature, making it more durable that a typical ceramic tile.

Average Cost/Sqm: $50 – $130 (Supply only)

Made similarly to a porcelain tile, ceramic tiles are kiln fired at a lower heat making them less dense than a porcelain tile, therefore more prone to cracking.

Average Cost/Sqm: $36 – $95 (Supply only)

Wook look tiles are either a porcelain or ceramic tile with a digitally printed wood effect on the surface layer.

Average Cost/Sqm: $59 – $99 (Supply only)

Other Flooring Options

Concrete slabs which have been grinded down with diamond-segmented abrasives to a desired gloss level and smoothness. The outcome is a glossy, mirror-like finish.

Average Cost/Sqm: $39 – $79 (Supply only)

Cork is made by grinding down the bark of a cork oak tree then kiln firing it creating wood-like sheets.

Average Cost/Sqm: $60 – $100 (Supply only)

Discover the price of your next project

Our patented design enables us to create extra wide boards that look amazing and last a lifetime.

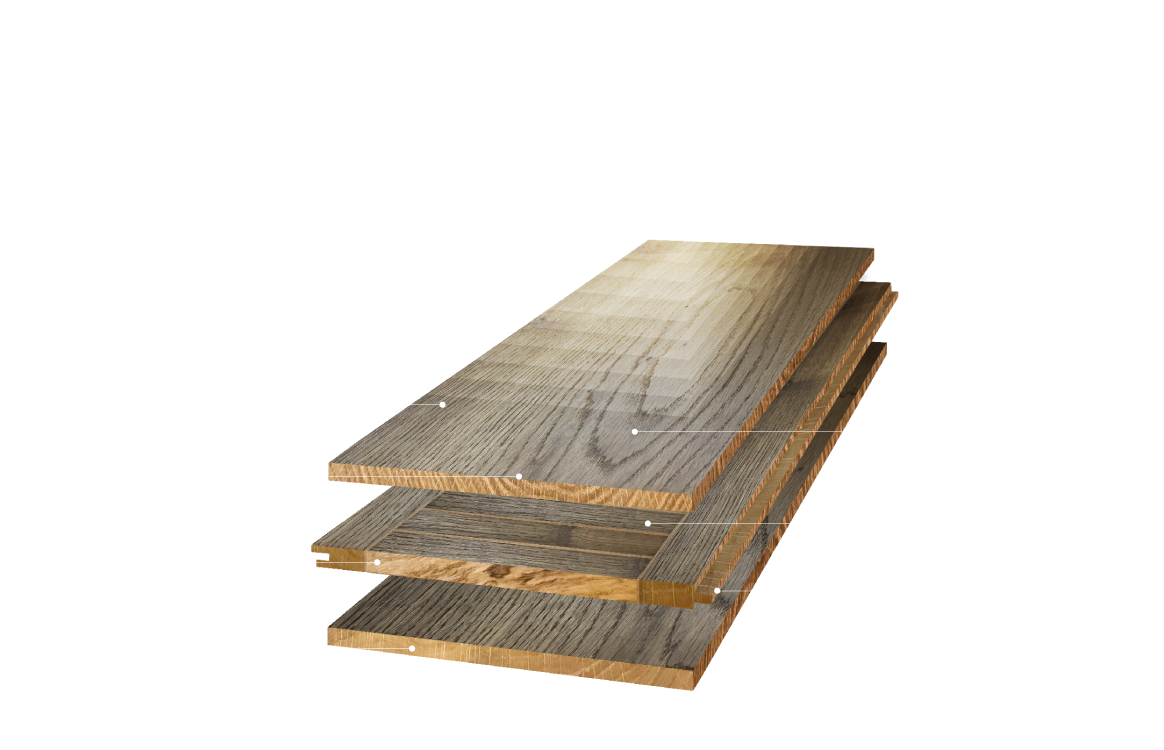

Every floorboard is manufactured using our world-first, patented Stabilised Solid® technology.

Get inspired by some of our flooring creations

Transform your home with our diverse range of Australian timbers and French Oak flooring.

All our floors are guaranteed to ensure true peace of mind

![]() Guarantee your floor will stay flat and perform its role for a lifetime.

Guarantee your floor will stay flat and perform its role for a lifetime.

![]() Guarantee your flooring price is secured once order is placed.

Guarantee your flooring price is secured once order is placed.

![]() Apply no penalties for change of mind on your choice of floor before delivery.

Apply no penalties for change of mind on your choice of floor before delivery.

![]() Ensure our flooring is installed with no harmful emissions.

Ensure our flooring is installed with no harmful emissions.

![]() Guarantee all of our timber is from sustainable sources.

Guarantee all of our timber is from sustainable sources.

Commonly Asked Timber Flooring Questions

What is a pre-finished wooden floorboard?

Pre-finished floor installations can be done in just days and walked on instantly.

What does cupping mean with timber floor?

All Lifewood floors manufactured with Stabilised Solid cross engineered technology which eliminates this problem and we back it up with a lifetime warranty.

This is an example of a cupping floor.

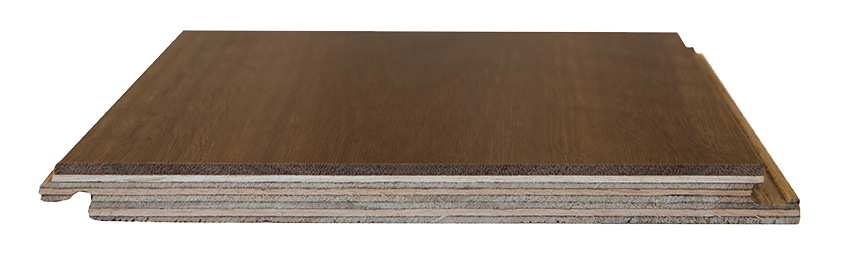

What is engineered timber flooring?

Lifewood floors are made from solid timber throughout the whole board (all 3 layers) and completely sealed to avoid any form of moisture damage.

What is a cross laminated timber floorboard?

How long until I can walk on my new floorboards after installation?

If you are installing raw timber flooring, you will need to leave the house while the floor is being polished and the curing process is taking place. This can take up to 5 days.

What are the advantages of a direct stick floor?

The advantages of this way of installation are that you can sand and polish the floor more times giving your floor a much longer lifetime, plus it eliminates hollow echo from under the boards.

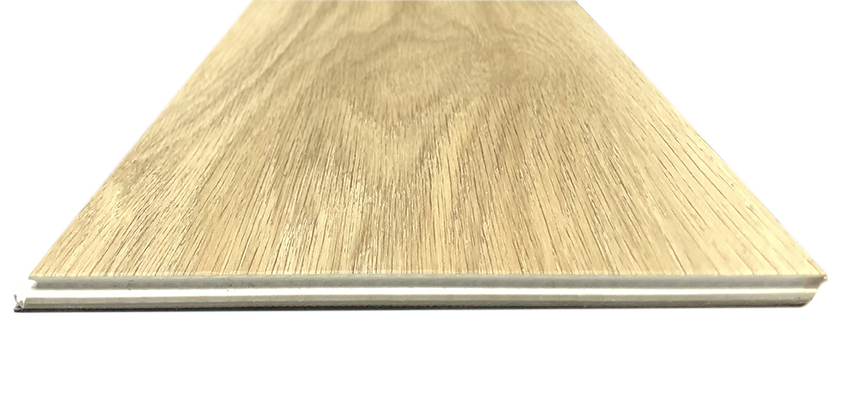

What is floating timber floor?

Floating floors typically have a tongue and groove which click into one another, making the installation process quick and easy.

The problem is a floating floor is seen as more of a temporary solution as you can’t sand and polish the surface layer.

Does timber flooring scratch easily?

We incorporate a metal oxide in each of the 7 layers of polyurethane finish making it one of the toughest and most durable floors available. However, it is fair to say that the floor can still get scratched but the finishes we use ensures minimal scratching.

We also supply you with a special care kit to help minimize the appearance of any scratches.

How many times can a timber floor be sanded back?

The denser the floor the more sanding you will be able to get out of them. Our experience indicates that you should expect to get a minimum of 2 – 3 sanding out of a well manufactured floorboard.

Can you install timber flooring over underfloor heating?

Can I lay timber floor over tiles?

1. If the tiles come loose from the sub floor it could potentially cause damage down the track as you can’t guarantee how well it’s sealed from moisture.

2. Tile floors are rarely perfectly flat so when your timber floor is installed it will have some hollow sounding areas.

3. The other thing we must check is that the glue used bonds well to the surface of the tile.

In most cases we recommend that the floor be wiped over with methylated spirits and given a light sanding to ensure the glue bonds sufficiently.

Beauty meets longevity

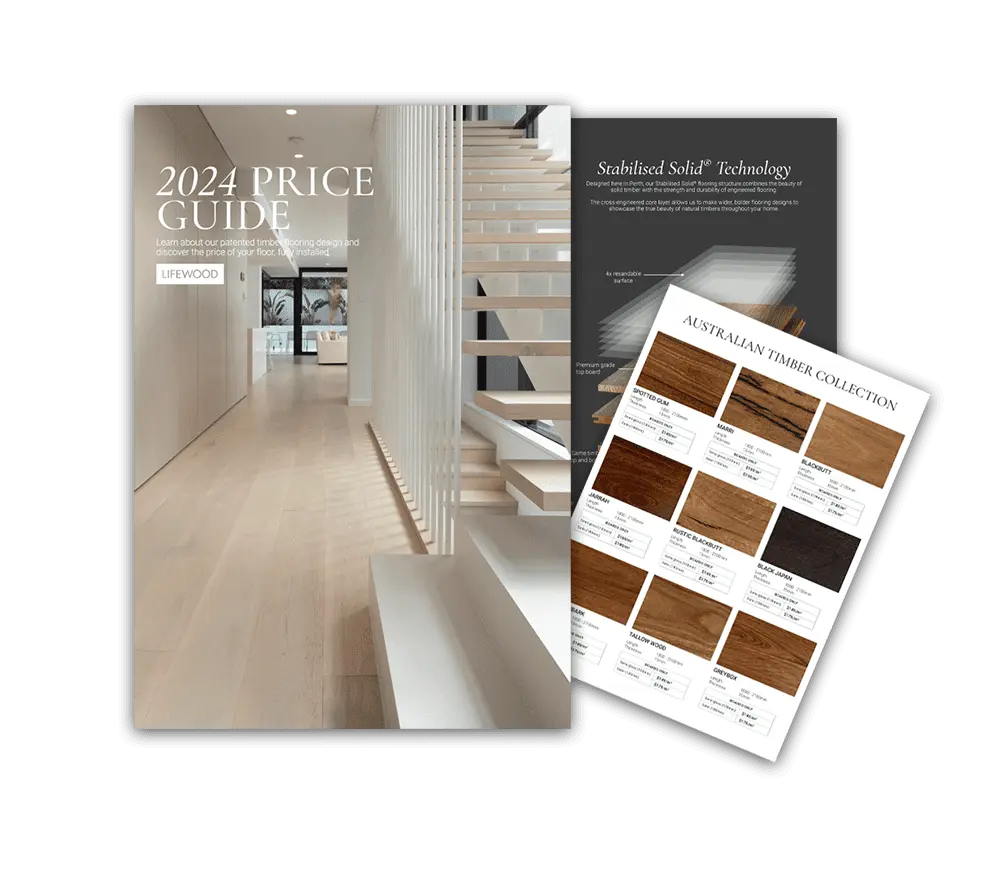

Download

Price Guide

Your details are kept confidential

4.7 from 250 reviews