Engineered Timber Flooring Perth

Lifewood Engineered Timber Floorboards

Combine Exceptional Hardness and The Best Structure

Lifewood offers the best engineered timber flooring that combines beauty and structure. OUR STABILISED SOLID® TECHNOLOGY COMBINES THE STRUCTURE OF ENGINEERED TIMBER FLOORING WITH THE LOOK AND FEEL OF SOLID WOOD FLOORBOARDS

World-class engineered timber floorboards designed to look forever young with lifetime warranty

ALL LIFEWOOD ENGINEERED TIMBER FLOORS ARE DESIGNED TO LAST A LIFETIME. THAT IS WHY WE BACK THEM UP WITH A LIFETIME WARRANTY

Discover the engineered timber flooring cost for your home – fully installed

How Lifewood floorboards compare to the rest of the market

OUR PATENTED ENGINEERED HARDWOOD FLOORING TECH ENABLES US TO MAKE A STRONGER, WIDER & MORE SUSTAINABLE TIMBER FLOORBOARD

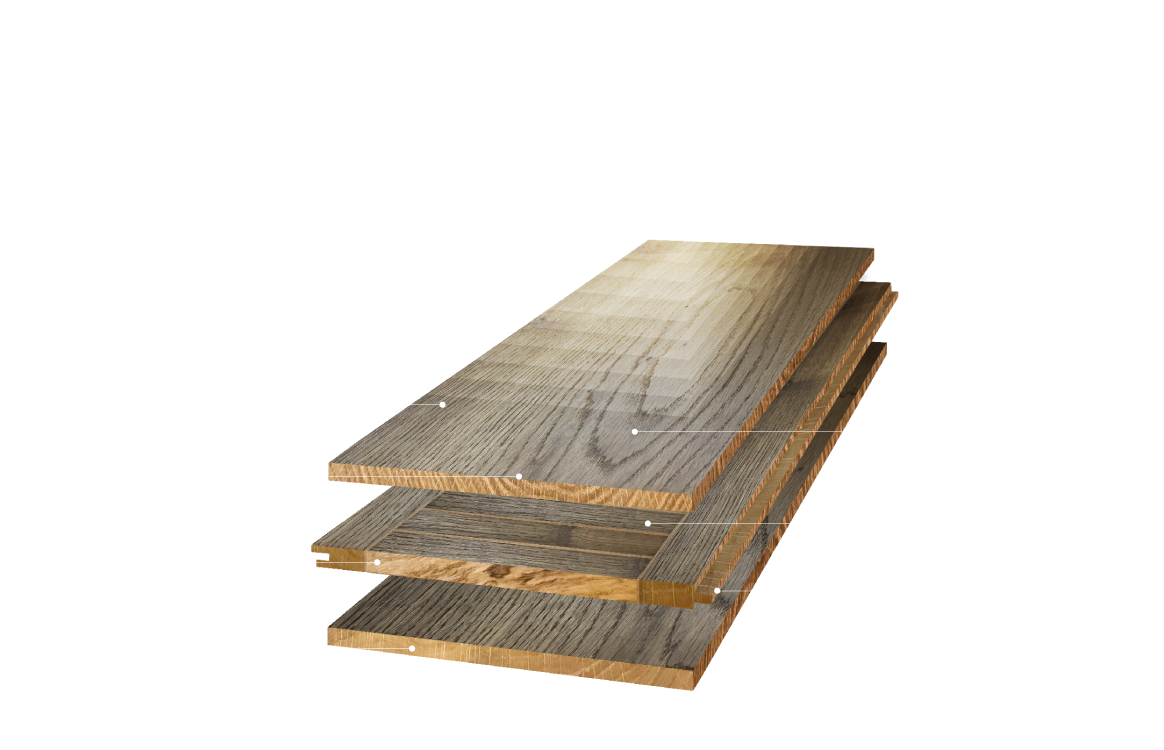

Take a look inside our patented Stabilised Solid® engineered flooring design and our engineered floorboards technology

Every floorboard is manufactured using our world-first, patented Stabilised Solid® technology.

Our engineered flooring innovation combines the best of both worlds

WE SOURCE ALL OUR OWN MATERIALS AND HANDCRAFT EVERY TIMBER FLOORBOARD TO GUARANTEE QUALITY AND ETHICAL LOGGING PRACTICES

Lifewood’s Stabilised Solid® WOOD Floorboard

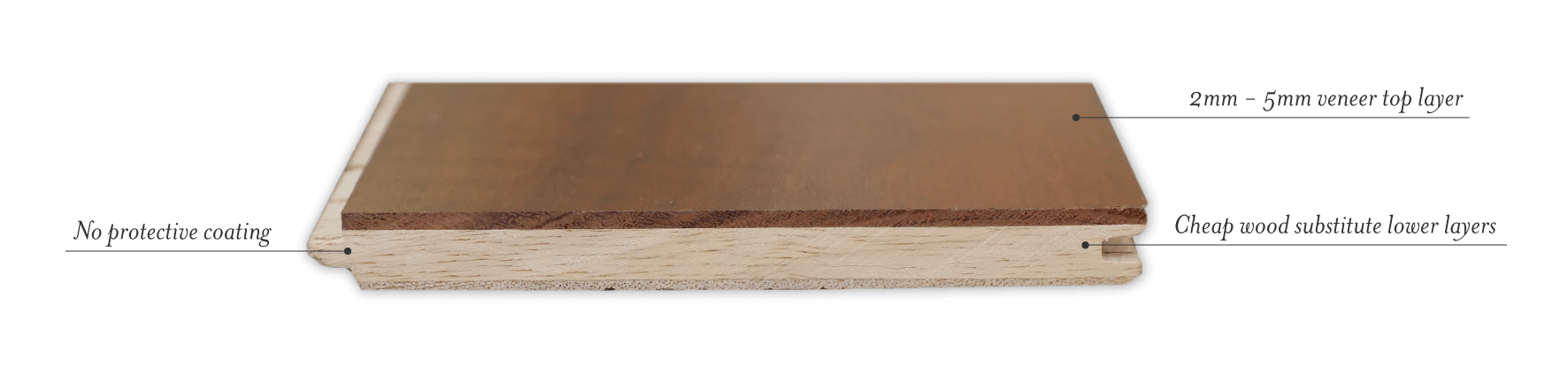

Typical Engineered Flooring (what we DON’T do)

Discover the engineered timber flooring cost for your home – fully installed

How many times can you resurface our wood floorboards?

THE SANDING LIFE OF A TIMBER FLOOR IS DETERMINED BY THE HEIGHT OF THE TOP LAYER

A typical sanding will take 1mm off the floor’s surface.

Give your wood floor a fresh new look every 10 to 15 years!

How does Lifewood timber flooring make differences

A life-proof wood floor suitable for the whole family

Water Resistant

Easy to Clean

Scratch Proof

Low Emissions

Pet Friendly

Eco-friendly

Our pre-finished design makes the installation quick and convenient… walk on your wooden floor the same day!

The benefits of pre-finished i.e. engineered timber flooring

![]() There is no mess!

There is no mess!

![]() Your home won’t stink

Your home won’t stink

![]() You won’t need to move out of your home during installation

You won’t need to move out of your home during installation

![]() Scratch resistance is much higher with more layers of coating

Scratch resistance is much higher with more layers of coating

![]() No acclimatising is needed of the board

No acclimatising is needed of the board

![]() No ugly nail holes in your floor

No ugly nail holes in your floor

![]() Easier to replace damaged floorboards without re-coating your whole floor

Easier to replace damaged floorboards without re-coating your whole floor

Premium staircase designs

TURN YOUR STAIRCASE INTO A DESIGN CENTREPIECE WITH PREMIUM ENGINEERED TIMBER FLOORING PERTH HAS EVER SEEN

Discover the cost of your floor – fully installed

Engineered Wood Flooring Masterpieces by World-Class Craftsmen

All Lifewood installers are true artisans of their trade, handpicked for their eye for detail, and work ethic.

To create an outstanding wood floor you’re going to need a masterful craftsman to bring it to life.

All our installers are passionate about their craft, transparent in their work, and go the extra mile to create the wood floor of your dreams.

Matching accessories to match your beautiful floor

CREATE A SEAMLESS LOOK THROUGHOUT YOUR HOME WITH MATCHING FINISHINGS

BEADING

STAIR NOSING

SKIRTING

Our guarantees to ensure true peace of mind

![]() Guarantee your floor will stay flat and perform its role for a lifetime or we will replace or repair your floor at our expense.

Guarantee your floor will stay flat and perform its role for a lifetime or we will replace or repair your floor at our expense.

![]() Guarantee you won’t pay a cent more than our agreed price or additional expenses will be covered by us.

Guarantee you won’t pay a cent more than our agreed price or additional expenses will be covered by us.

![]() Will pay to have your whole home professionally cleaned top to bottom if our installer leaves your home without cleaning up. All rubbish will be removed by us.

Will pay to have your whole home professionally cleaned top to bottom if our installer leaves your home without cleaning up. All rubbish will be removed by us.

![]() If the coating on your floor doesn’t perform to industry standards, we’ll rectify the floor at our expense.

If the coating on your floor doesn’t perform to industry standards, we’ll rectify the floor at our expense.

![]() Apply no penalties for change of mind on your choice of floor before delivery.

Apply no penalties for change of mind on your choice of floor before delivery.

![]() Will never use a plywood, rubber wood (Hevea) or pine base in residential homes (termites love plywood).

Will never use a plywood, rubber wood (Hevea) or pine base in residential homes (termites love plywood).

![]() Ensure our flooring is installed with no harmful emissions.

Ensure our flooring is installed with no harmful emissions.

![]() Will never use any product harvested from illegal logging.

Will never use any product harvested from illegal logging.

Here’s what our customers have to say

Recognition from acclaimed awards

Engineered Timber Flooring FAQ

1. What is engineered timber flooring?

An engineered timber floor is a multi-layered floor composed of a timber veneer or lamination surface layer sitting on a cheaper substrate of ply, pine or rubber wood. The top layer of timber is generally thin (1mm – 4mm), making it easier to age and condition the wood, drastically reducing the expansion and contraction. Without having to worry about these humidity issues the manufacturer can create a pre-finished floorboard that doesn’t require any sanding or polishing after installation. With an engineered floor you can have the wood delivered, laid, and be walking on all in the same day.

2. How long will my engineered floor last?

This will depend a lot on how the floor is installed. Most companies will float an engineered floor which means they stick the boards together but there’s nothing holding the floor to the ground. This is a very quick and easy way to install a floor, but it restricts you from sanding and re-polishing the floor in the future. You can’t sand and re-polish a floating floor.

3. Why do we innovate engineered timber flooring ?

Engineered timber flooring does have some design benefits. It’s hard to find a solid timber floorboard that’s any wider than 100mm, purely because the wider and thicker the board is, the harder it is to keep it from expanding. With an engineered timber floor, you can create much wider planks exposing more of the wood’s natural textures. Wider boards will give your home an open plan look and makes it feel more spacious.

4. Pros and cons of engineered timber flooring

Pros

- Cheaper than solid timber (cost-effective)

- Quick and clean installation process (easy to install)

- Doesn’t need to acclimatize before installation

- More stylistic variations available (more options)

Cons

- Doesn’t age gracefully

- Not as durable

- Susceptible to water and spills

- Cheaper wood underneath isn’t as strong as hardwood

- Can’t sand and polish if it’s a floated floor

- More susceptible to termites and white ants

- Typically no warranty when glued down

- Sounds cheap and hollow to walk on

5. What is solid timber flooring?

A solid timber floor is a traditional style hardwood floor which is a solid piece of wood all the way through. This style is more common in older houses all around Australia.

Solid timber floor typically comes as a raw product (as appose to pre-finished) meaning after the boards are laid the installer will also need to sand and polish the whole area. Solid timber flooring looks amazing, ages well, and can be re-sanded and polished numerous times which makes it a great long-term option.

Sounds great right? Well here’s the thing most consumers don’t realise…

Solid timber flooring will expand in humid conditions and contract in dryer periods. For a manufacturer, there is true art in making the perfect solid-engineered timber floorboards. To minimize the expansion and contraction after installation the wood must be kiln-dried and aged to achieve a perfect moisture level in the wood.

True masters of flooring manufacturing will always use a process called hysteresis to age and balance the timber to reduce movement once installed.

If the wood is dried too much, or too fast, it will become brittle and lose its aesthetic appeal. On the other hand, if there is too much moisture in the board it will expand and contract. The problem with board expansion is it forces the boards to push against each other causing them to rise or cup. When boards contract they shrink leaving large ugly gaps in your floor.

Even after this rigorous process of treating the wood, you will still need to acclimatise the engineered floorboards to the environment where they will be laid. This process is known as E.M.C (Equilibrium Moisture Content). When installing solid timber flooring in your home you should leave the engineered timber floorboards in the area where they will be laid for up to 6 weeks to further adapt to the relative humidity of your location.

6. Pros and cons of solid timber flooring

Pros

- Premium look and feel

- Very smooth surface with no joining edges

- Easy to clean and maintain

- Less susceptible to termites

- Ages gracefully

- Solid and can be a more stable board

- Very warm feel for your home

- Can be sanded and polished multiple times

- Can last a long time last a long

Cons

- Coating isn’t as tough as pre-finished

- Less sustainable to the log resource

- Takes up to 6 weeks to install

- Very dusty and messy installation process

- Have to move out of your home when sanding

- Shorter and randomly sized boards

- Restricted to narrower boards due to stability issues

- Very difficult to match timber moisture to the

- household EMC

- Typically nailed to the ground

- Not suitable for pre-finished

- Repair and replacement requires full sand and polish

- More expensive

7. What Is Lifewood Stabilised Solid Timber Flooring?

As you can see there are many pros and cons in both solid and engineered timber flooring. For this reason, we’ve created a revolutionary new board which incorporates the benefits of both.

Lifewood founder Mark first created this technology out of desperation to save his original business Bamboozle from bankruptcy. The biggest problem with bamboo flooring was finding a method to create a solid board that stays flat.

Coming from both an artistic family on his mother’s side, and a lineage of inventors and botanists from his father’s side, what really drives Mark was his passion for creating innovate solutions to complex problems. Since developing this technology for the bamboo market, Mark has extended it’s functionality for timber flooring and transformed Bamboozle into Lifewood Handcrafted Flooring to fit our extensive range of timbers.

We call this technology Stabilised Solid and it has enabled us to create a solid floorboard that can be pre-finished, sanded, and polished up to 5 times. Its versatility allows us to create all kinds of sizes and colour blends.

Stabilised Solid has 3 layers of solid timber (top 5mm, middle 5mm, bottom 5mm), the middle layer being the essential core layer. This core layer is lined with timber sections all laid on a right angle giving it the ability to yield the natural movement of its environment, holding this movement entirely within its core.

Not only does this prevent the big issue of solid timber expanding and contracting, we have also gone to great lengths to make our board much more scratch and water-resistant. All our boards have very low VOC emitting coating which we apply to all 6 sides of every board.

This means you can have a floor that looks amazing and feel at ease that it’s not going to be easily damaged.

8. Pros and cons of Lifewood Stabilised Solid Timber Flooring

Pros

- Solid timber used from top to bottom making every board more stable

- Advanced manufacturing procedure eliminating expansion and contraction of the board

- All our boards come pre-finished and can be walk on the same day – no dust or mess

- Thick top layer which can be sanded and polished 4 times

- Low VOC emissions in the glue

- Sustainable manufacturing process which uses the whole tree, even the saw dust to heat the kilns

- Hard-wearing coating offering more damage protection

- Moisture resistant

- Lifetime warranty on all our floors

Cons

- More expensive than engineered

- Challenging scientific processes to make and manufacture each board

- Not as readily available

9. Click Here to Check Out More About Lifewood’s Patented Stabilised Solid Timber Flooring Technology

Beauty meets longevity

Download

Price Guide

Your details are kept confidential

4.7 from 250 reviews